“Health and Safety occupy a significant place to lead a happy, energetic and progressive lifestyle.”

PREMISE

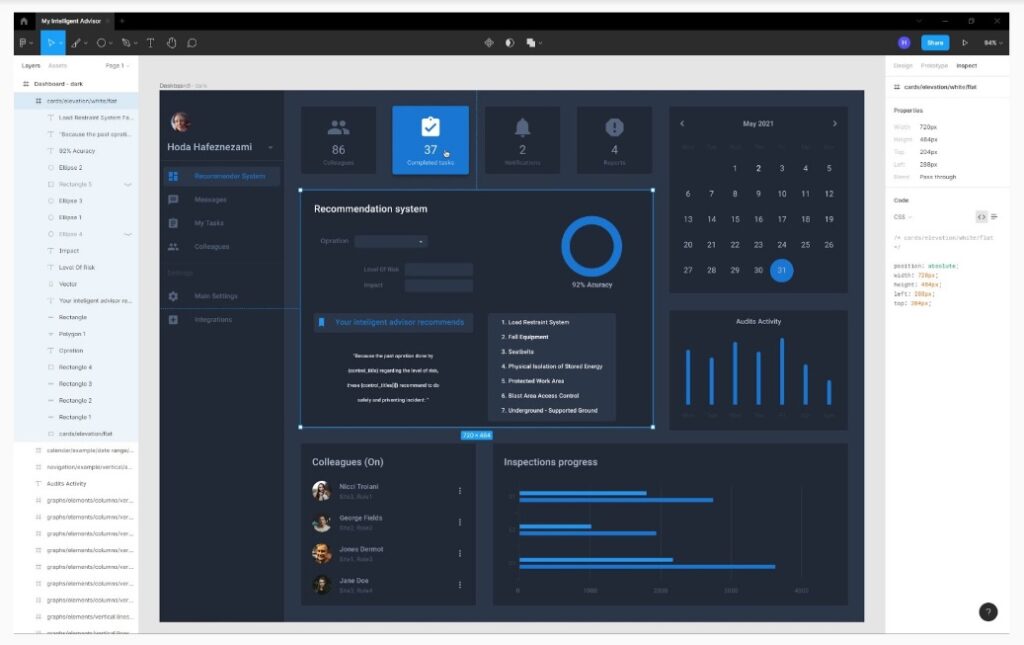

A recommendation-based decision support system to help workers safety -safety specialist- and prevent work-related incidents in the industrial work processes

SYNOPSIS

Work-related injury and fatality have been recognized as a serious public health and safety concern. This problem becomes more vital in hazardous workplaces of industries such as oil, aviation or nuclear power because incidents in their environments can lead to major catastrophes besides negative effects on the environment, economy and healthcare. Incidents are inevitable during industrial processes resulting from machine defects or human factors. To reduce these incidents, “safety management” plays a key role to define ‘a systematic control of worker performance, machine performance, and the physical environment’ (Heinrich,1980). In this regard making critical decisions are frequently applied to maintain and ensure safety, among a huge amount of raw data which can cause “decision fatigue”. This study investigates the effect of using a data-driven decision support system on operational safety assurance activities. The proposed system aims to recommend the most effective safe control operation. Also, it facilitates multiple additional control recommendations based on the level of hazard risk during decision-making as part of the control of work. Finally, it will be discussed if a data-driven machine learning approach integrated into a safe industrial ecosystem can reduce human factors and boost safety.

SUBSTANTIATION

Work and work-related hazards can outcome injuries and endanger workers’ health and safety (Schulte, 2012). More than 2.7 million workers die from occupational accidents and work-related diseases every year, and 374 million workers suffer from non-fatal occupational accidents (Hämäläinen, 2017; Takala, 2017). During the last 100 years addressing occupational accidents, work-related diseases and deaths have been increasingly recognized as a primary international challenge relative to fulfilling social justice and sustainable development. Although much progress has been made, the challenge of creating a safe and healthy workplace for all remains today (ILO, 2021).

Technological developments have an impact on all aspects of work, including who or what performs the work, how and where work is conducted, how work is organized and affect the working conditions and changed safety and health of workers. These changes and developments are accelerating and revolutionary, yet they have both positive and negative implications for worker safety, health, and well-being. Consequently, it has been proposed that the world of work is going through a fourth industrial revolution. It is being driven by the digitalization of information (Schwab, 2016).

Besides related developments such as artificial intelligence and machine learning, new analytics, autonomous vehicles, innovative human-machine interfaces, the internet of things, big data, and cloud computing are all becoming increasingly regular (Stacey, 2016, 2017). These smart technology and wearable smart devices made safety and health opportunities for safety managers to monitor workers’ behaviours and communicate safety and health advice and information to workers in real-time. However, it may also make new risks, resulting in increased human-machine interfaces, which can lead to more consideration about psychosocial and organizational factors to managed changes; that needs to improve safety management.

Safety management is defined as “a systematic control of worker performance, machine performance, and the physical environment” (Heinrich, 1980); for organizing this systematic control, the safety management system integrates all safety management operations into a logical sequence (Li, 2019). It generally has practised three steps: individual risk management, severe training and accident investigation; technology, regulations and incident investigation; business management approach to safety and routine collection and analysis of operational data.

Managing safety is a multifaceted endeavour that requires an organization’s determination of safety requirements (Strutt, 2006); create a safety management structure and procedure to make decisions which operations must be carried out in order to meet pre-determined safety standards and requirement. In everyday operations, making decisions based on the likelihood of future events is routine. However, the concept of decision fatigue states that after making several decisions, a person’s capacity to make additional, informed decisions is adversely affected.

To achieve a regulated status of the oil platform, the theory of control system integrates the human/operator factor benefit, maintenance feature effectiveness, component protection quality assurance system, and safety measurement system in a holistic manner. Learning from the past incident was the main reason to choose a recommendation system, also recommending a suggestion as to the main feature of this system (RS), was another advantage to provide authority and confidence in high-risk workplaces.

Yet in many domains, it is much more acceptable that the final choice and responsibility remain with a human decision maker, but additional advice is provided with a machine.

PROTOTYPES / EXPERIMENTS

Data collection

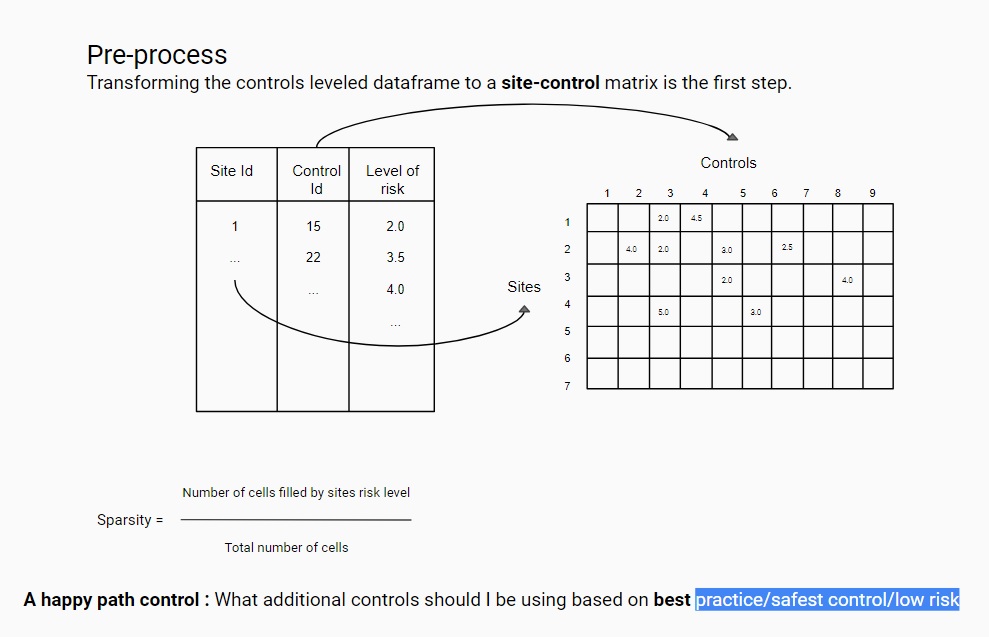

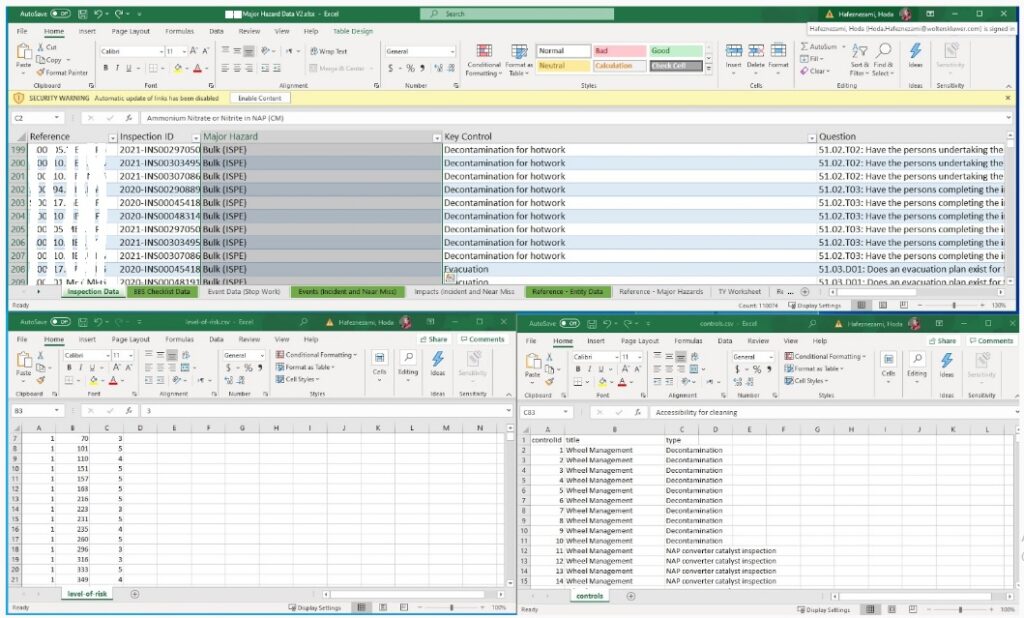

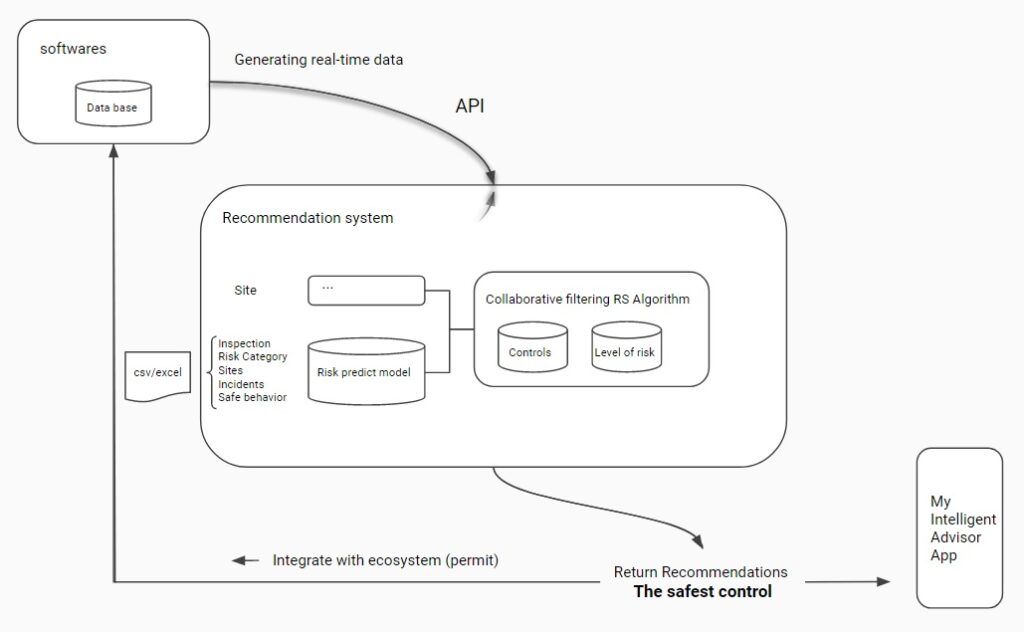

For collecting data first, it needed to have insight about transforming data into a recommendation system algorithm. In conventional recommender systems, data returning a user’s preferences are collected from explicit and implicit input. Where the explicit expression of preference usually is provided as item scores, implicit information can be derived from clicked items, items being part of the shopping basket, or visited pages, respectively. Whereas here, the preference for a safe operation is derived from the level of risk control. Hence, a dataset result from a “risk level predicts” as pre requisition provided by a company product to compare with its result after using the prototype. Finally based on the company paradigm and compares of productivity of the new product with the previous level of risk, can estimate the effectiveness of adding a recommendation system as an advisor to entered to safety ecosystem.

Implementation and training of the model

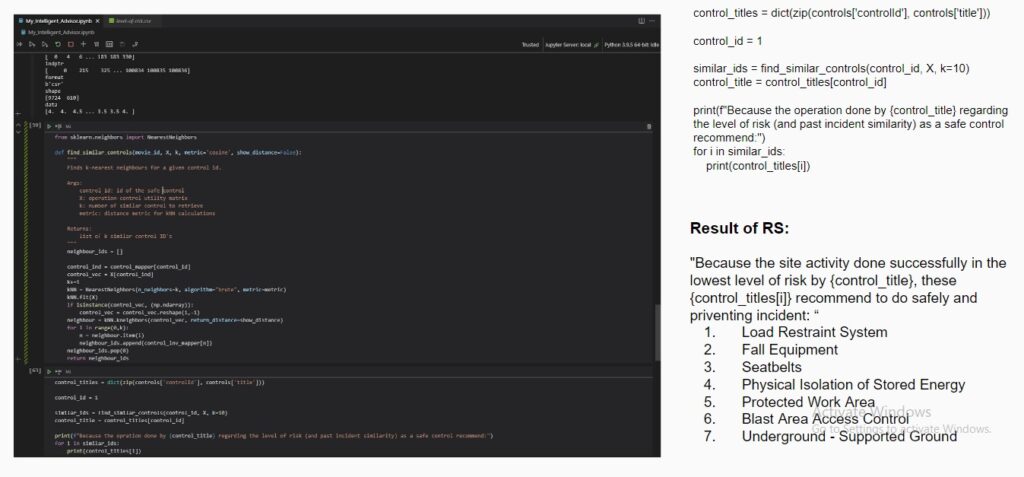

I start deployment with coding in the Jupyter notebook using two data set include ‘level-of-risk.csv’ and ‘controls.csv’. For the first iteration of the prototype, I developed a recommendation system based on a collaborative filtering algorithm. Along with coding, I start to design the final interface by Figma. Then I used HTML/CSS to code to show the result in “My intelligent application”. To prepare for the first iteration of the prototype the final tool will be designed by Figma. Also based on the proposed architected an application designed to integrate with the whole system.

Iteration

The algorithms described in the following aim at recommending the potentially most effective safe control operation for a given Site based on its level of risk.

The collaborative filtering idea is transferred to the best-matched control site recommendation domain, considering controls/barrier as items and the Safest activity/ as site practice’ preferences based on their level of risk. For representing safe control, effectiveness is incorporated.

The *Level of risk could be replaced with *Impact or other possible variables.

My Github Link to access all code is here: https://github.com/HodaHafeznezami/Machine-Learning

CONCLUSION

In the first iteration of the prototype, I the test dataset prediction model by Python. Then design an algorithm to recommend a risk control operation. To deploy and implement the final application I needed to develop an app or a module and added it as a plugin component to the controlling software in use by companies.

Future Work

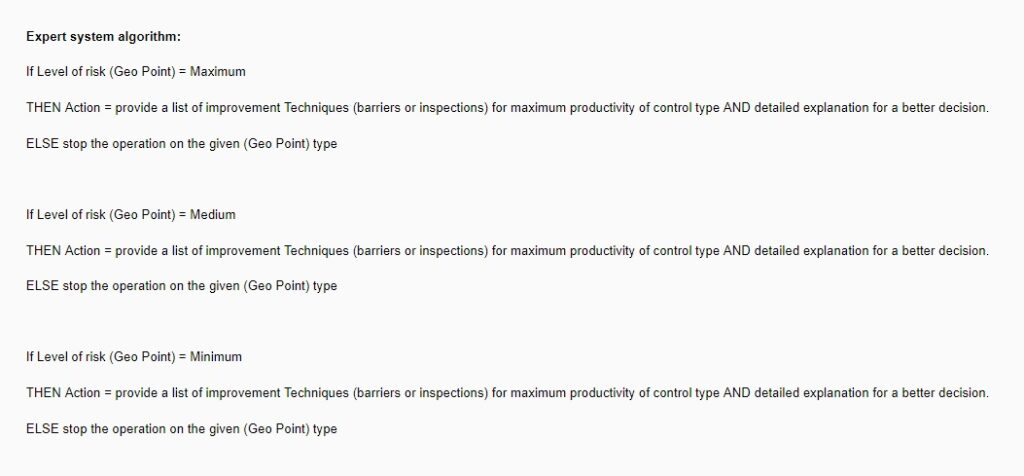

We can also add an Expert System to the Recommendation system as a hybrid model. A combination between ES and ML modelling to make certainty considering the importance of the context of use human health and safety. In this regard, I refer to the number of recommender systems used in clinical and healthcare context.

REFERENCES

Alli, B. O. (2008). Fundamental Principles of Occupational Health and Safety (second edition). International Labor Office.

Basra, G., & Kirwan, B. (1998). Collection of offshore human error probability data. Reliability Engineering & System Safety, 61(1–2), 77–93. https://doi.org/10.1016/s0951-8320(97)00064-1

Fingas, M. Oil Spill Science and Technology; Gulf Professional Publishing: Houston, TX, USA, 2016.

Liu, P., & Li, Z. (2014). Human Error Data Collection and Comparison with Predictions by SPAR-H. Risk Analysis, 34(9), 1706–1719. https://doi.org/10.1111/risa.12199

Montiel, H., Vílchez, J. A., Arnaldos, J., & Casal, J. (1996). Historical analysis of accidents in the transportation of natural gas. Journal of Hazardous Materials, 51(1–3), 77–92. https://doi.org/10.1016/s0304-3894(96)01819-5

Nancy G. Leveson, & Kathryn A. W. (2009). Safety Design for Space Systems.

Reason, J. (1997). Managing the Risks of Organizational Accidents. Ashgate.

Singh, H., Bhardwaj, N., Arya, S. K., & Khatri, M. (2020). Environmental impacts of oil spills and their remediation by magnetic nanomaterials. Environmental Nanotechnology, Monitoring & Management, 14, 100305. https://doi.org/10.1016/j.enmm.2020.100305

Swain, A. D., & Guttmann, H. E. (1983). Handbook of Human-reliability Analysis with Emphasis on Nuclear Power Plant Applications. Sandia National Laboratories.